-High precision and High reliability

-Repeatability: 0.4μm

-Minimum measurable tool: ?20μm

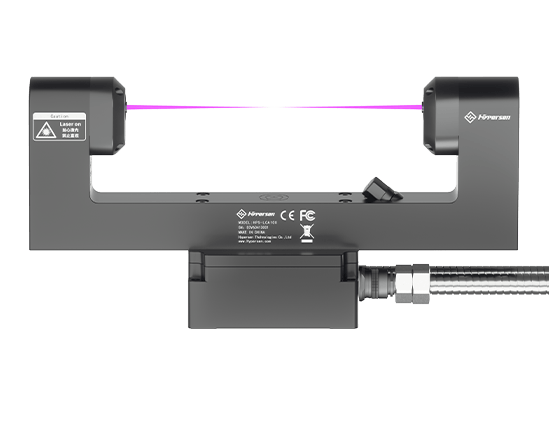

-405nm purple laser

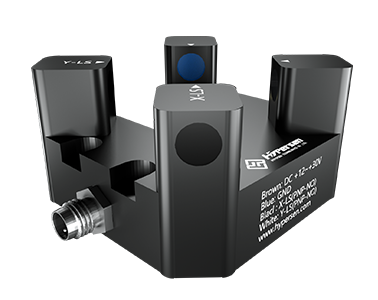

-Integrated design

-Excellent optical system and protective design

-Built-in tool cleaning system

-Only one cable and one air tube need to be connected

-IP68 protection

-Applicable to Aerospace manufacturing/Precision parts processing/Tool inspection/Auto parts processing

| Laser safety level | Class II | Laser type | purple laser/405±5nm/<1mW |

| Protection level(EN 60529) | IP68(Under working air supply status) | Input/Output | Three optocoupler inputs/Three optocoupler outputs/One analog output、RS-232 communication interface |

| Repeatability | 0.4μm 2σ* | Minimum measurable tool diameter |

φ20μm * |

| Maximum tool rotation speed | 200,000rpm | Power supply | DC 20V~26V |

| Weight | 1700g | Storage/operating temperature | -10°C~+70°C/+5°C~+45°C |

| Tool's diameter range | Vertical installation:φ20μm-φ500mm Horizontal installation:φ20μm-φ100mm | ||

| Air supply |

Diameter:6.0mm.Air pipe:5.0m,04MPa~0.6MPa,Air source must comply with GB/T13277-91 air quality level one requirements(water, oil and dust particles exceeding 0.1 micron are not allowed to enter the product through the air source). If it cannot be achieved, please choose our company's standard air source filter device. |

||

*Affected by installation conditions, installation stability, spacing and measurement mode

*All technical indicators are subject to the latest official product data manual

*The final right of interpretation belongs to Hypersen.